Portfolio >>>

matt egan (2019 - 2024)

Here’s a list of some of the larger personal projects I’ve worked on in the last few years.

While not all strictly related to

click to see more

Here’s a list of some of the larger personal projects I’ve worked on in the last few years.

While not all strictly related to

click to see more

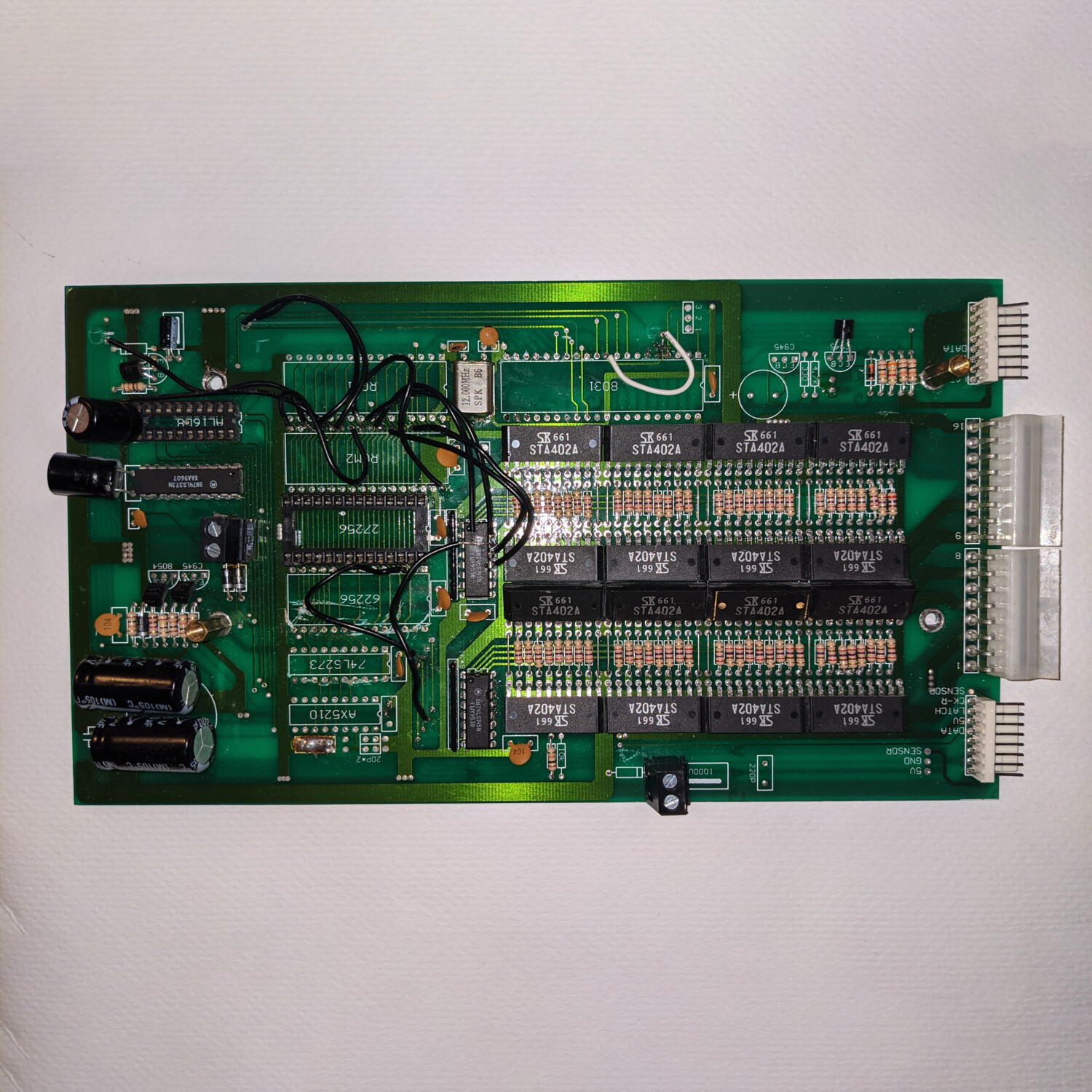

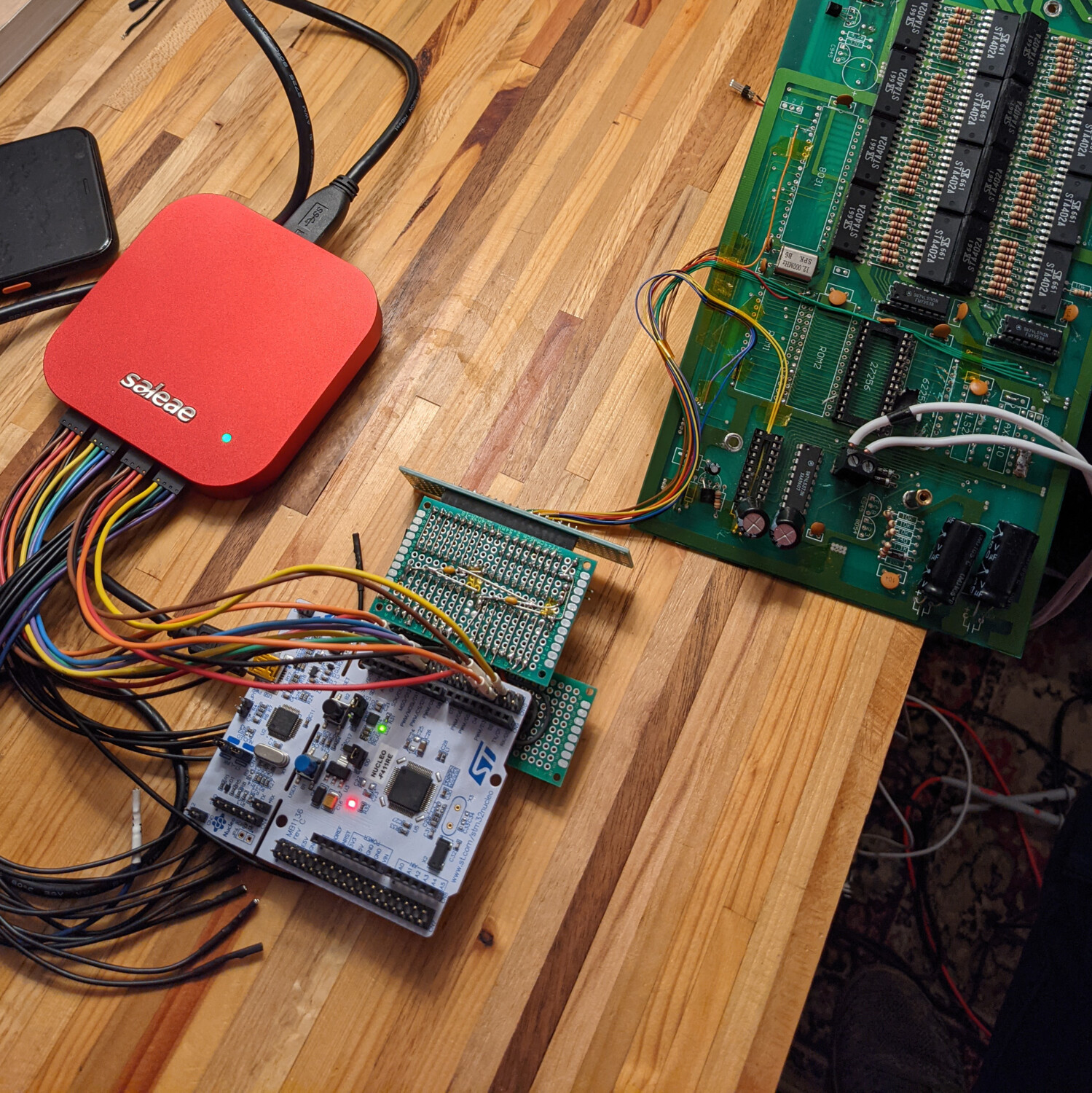

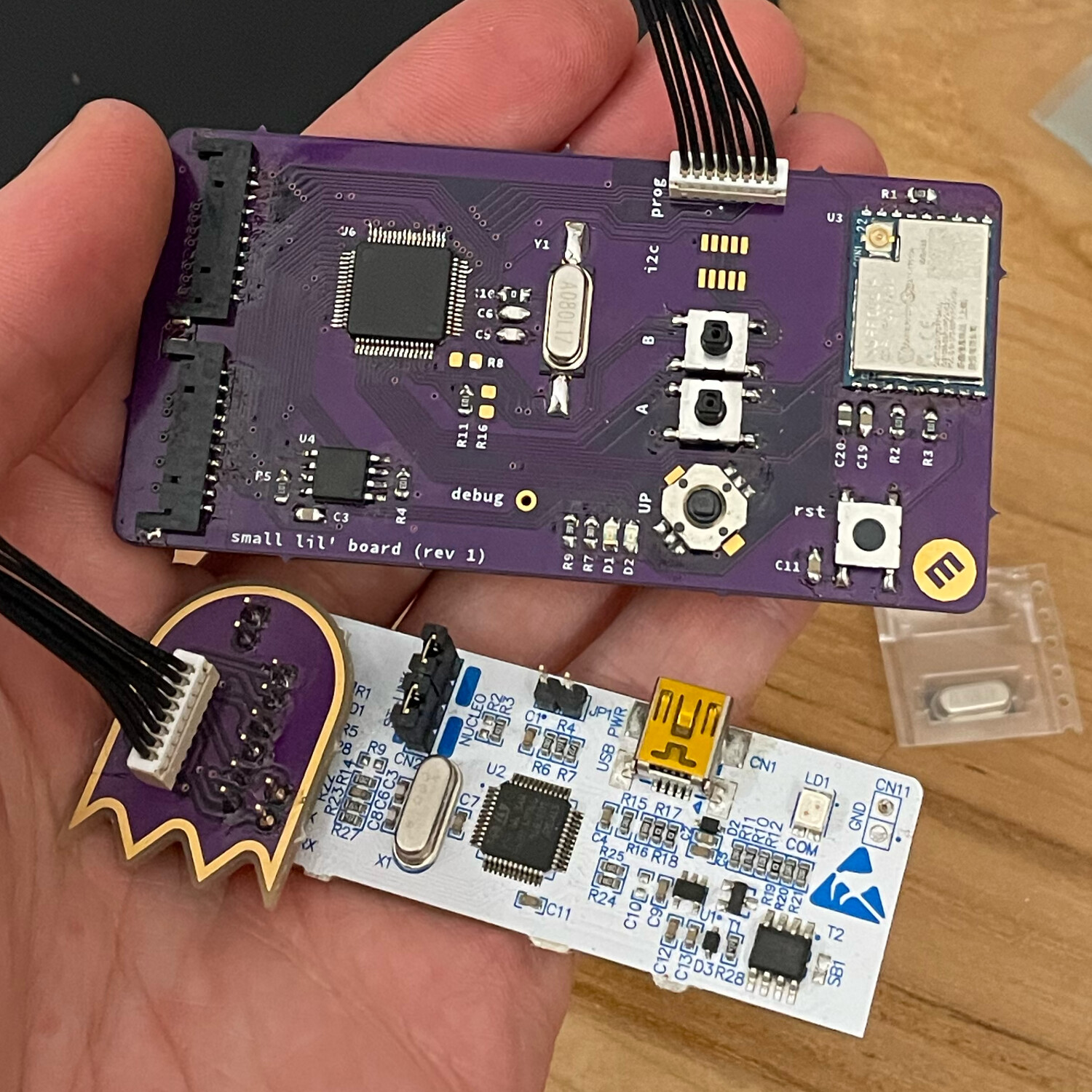

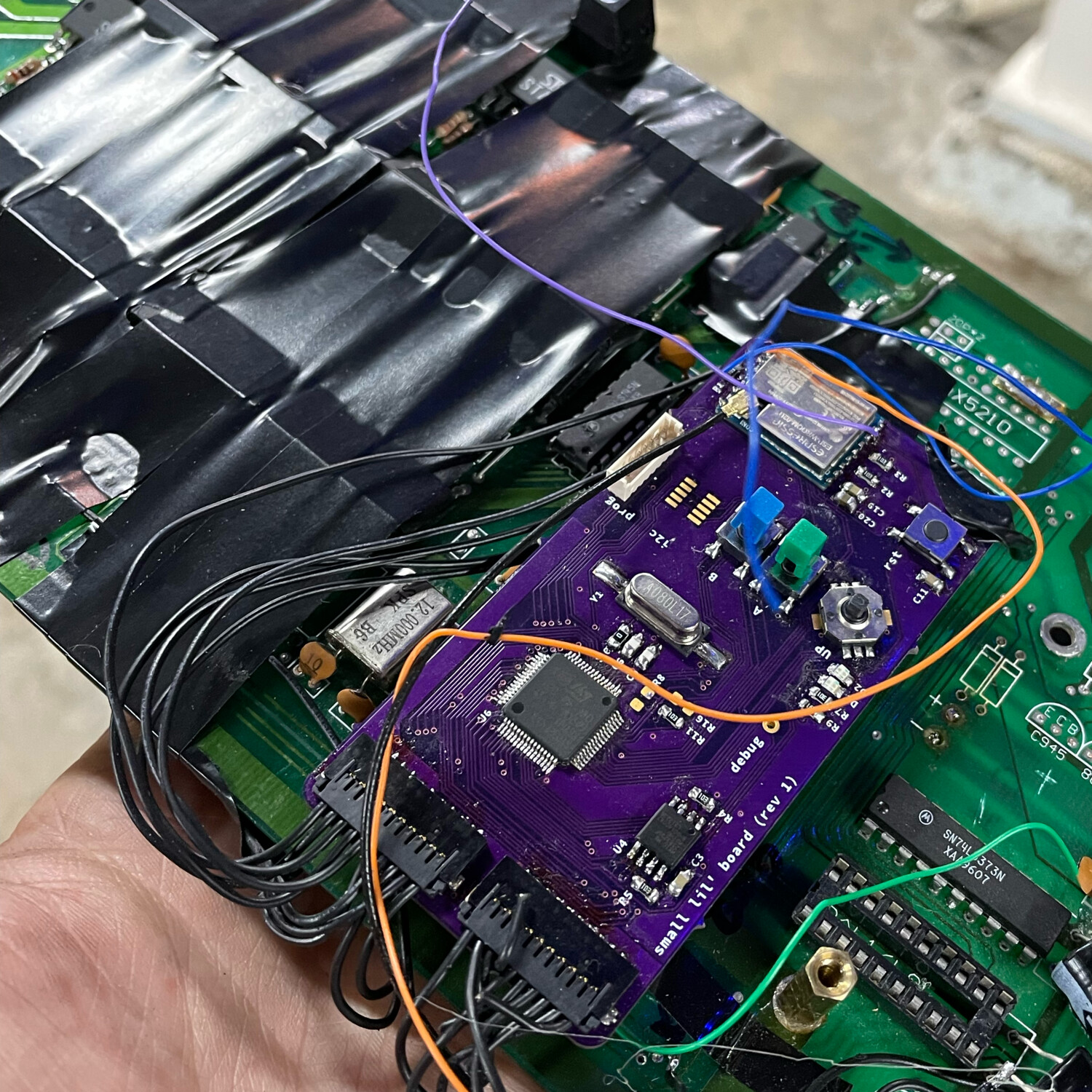

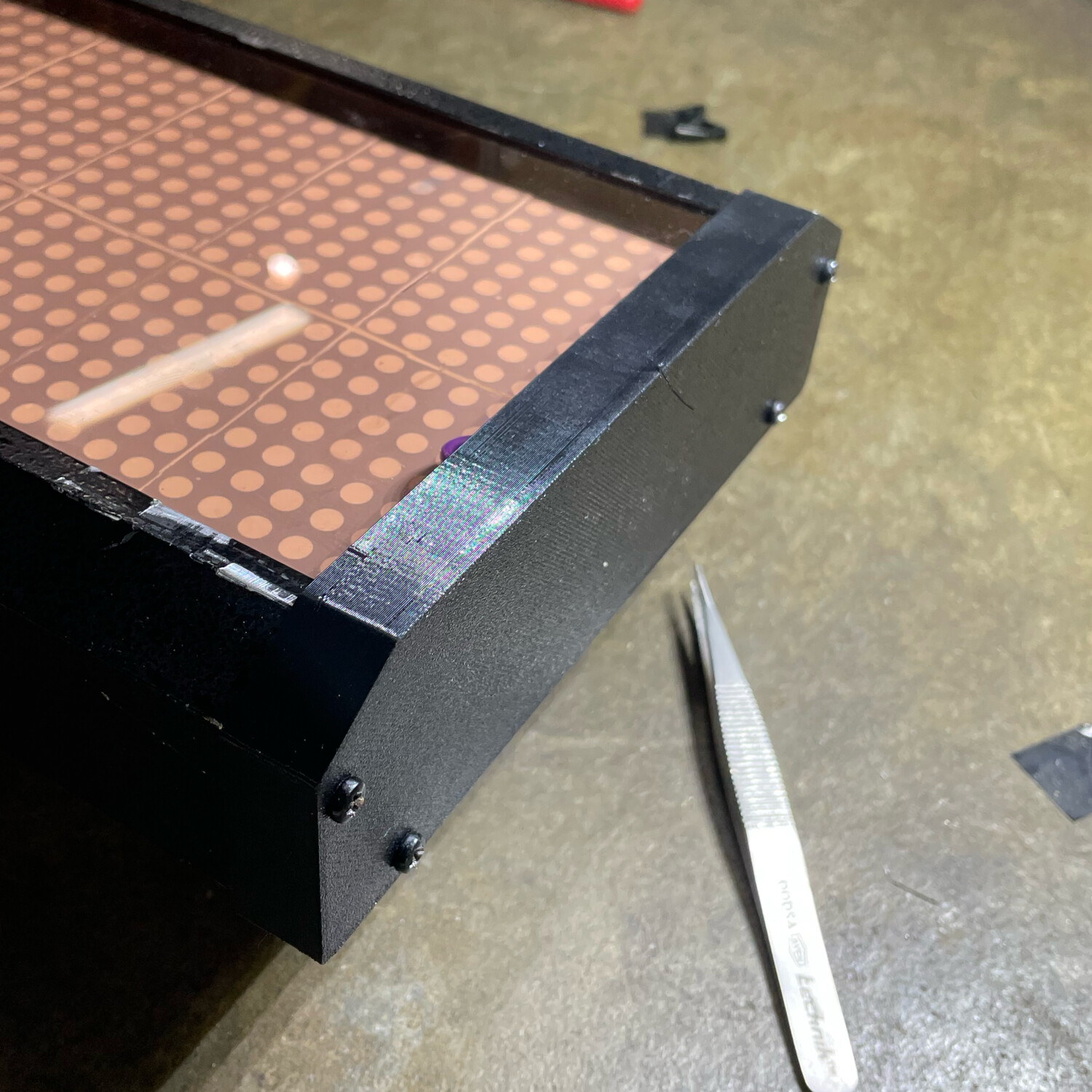

I found someone offering up a non-functional LED message board for free on a mailing list. Not being the type to turn down some free blinky lights (functional or not), I was obliged to take it home. I quickly found it to be missing its most essential components, but that made for a very fun project!

Project Included

I found someone offering up the pieces to a Mexican cargo bike on another mailing list. A few months later, I found myself preparing for Burning Man (this tends to happen to you if you live in the Bay Area), and I knew it would make the perfect playa bike. Having just finished the LED message screen a few weeks prior, I made it my stretch goal to include the display somehow. Even amongst the frenzy of planning the rest of the trip, I was able to go from buying wood at Home Depot to riding the bike in the desert in less than a week.

Project Included

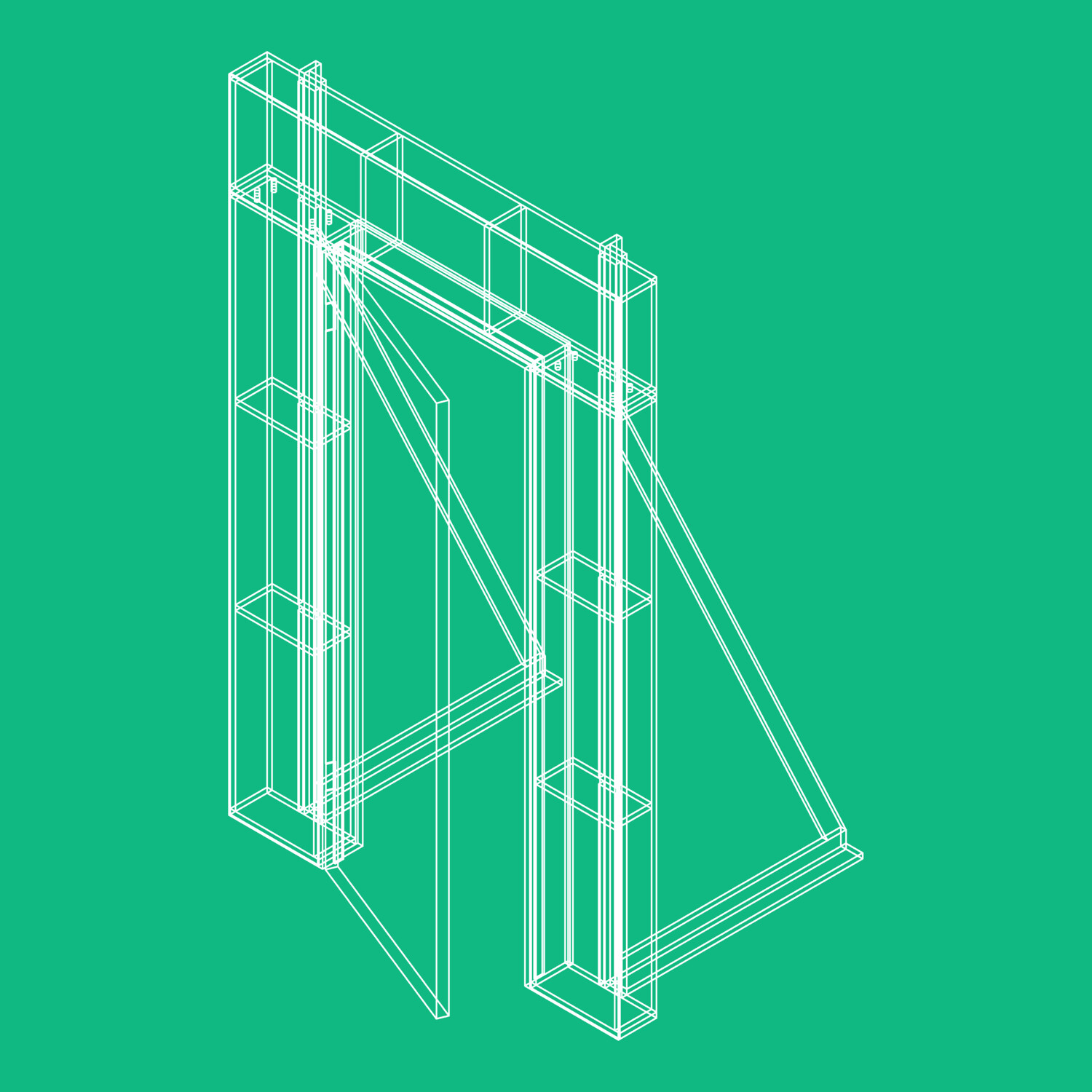

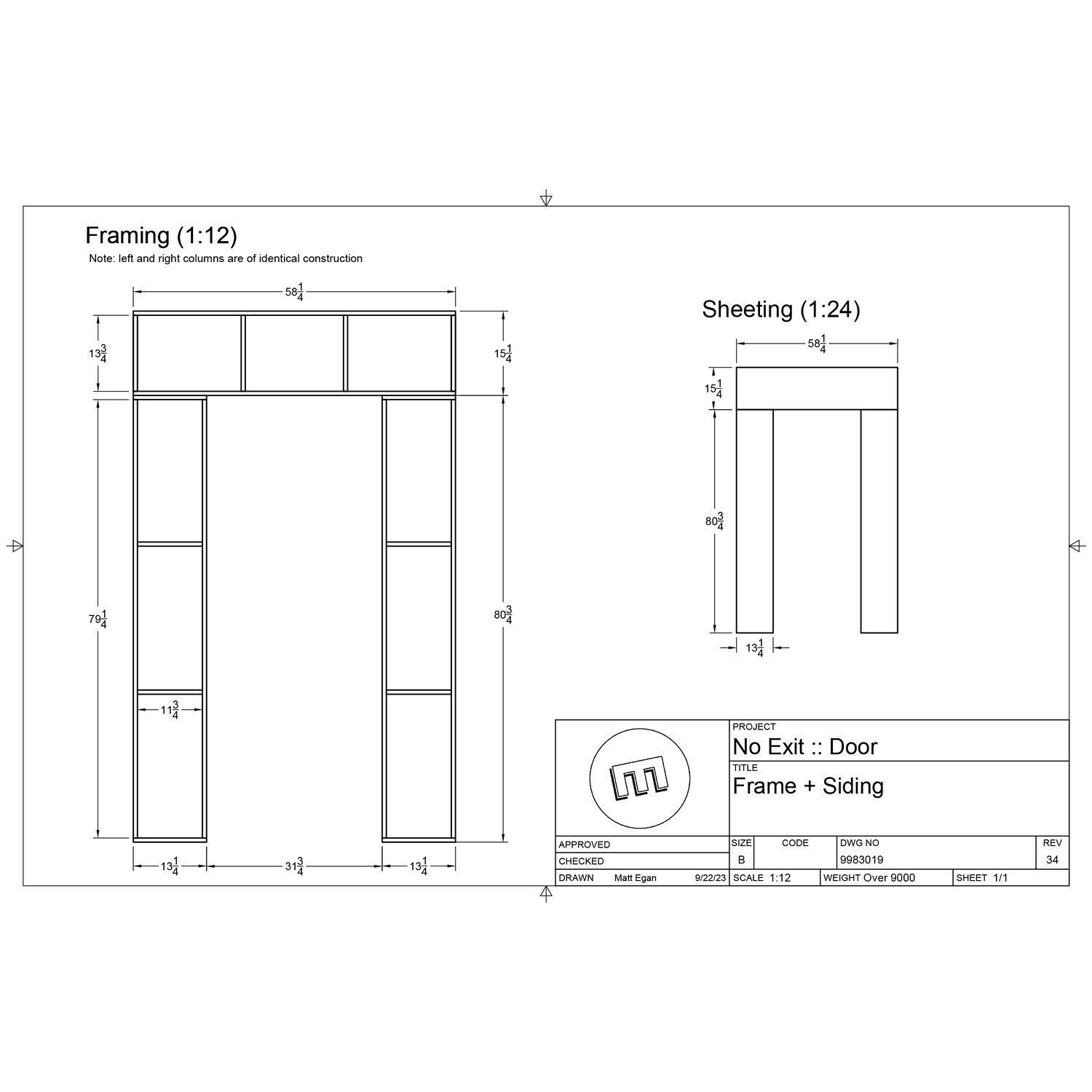

I consider myself extremely blessed to be surrounded by incredible friends who do some really extraordinary things. One such friend decided to put on a production of Sartre’s No Exit. I had never built any sort of stage prop before, but I’m never one to turn down a challenge, so I offered my help! In the span of a few weeks I constructed this functional, free-standing door flat.

Project Included

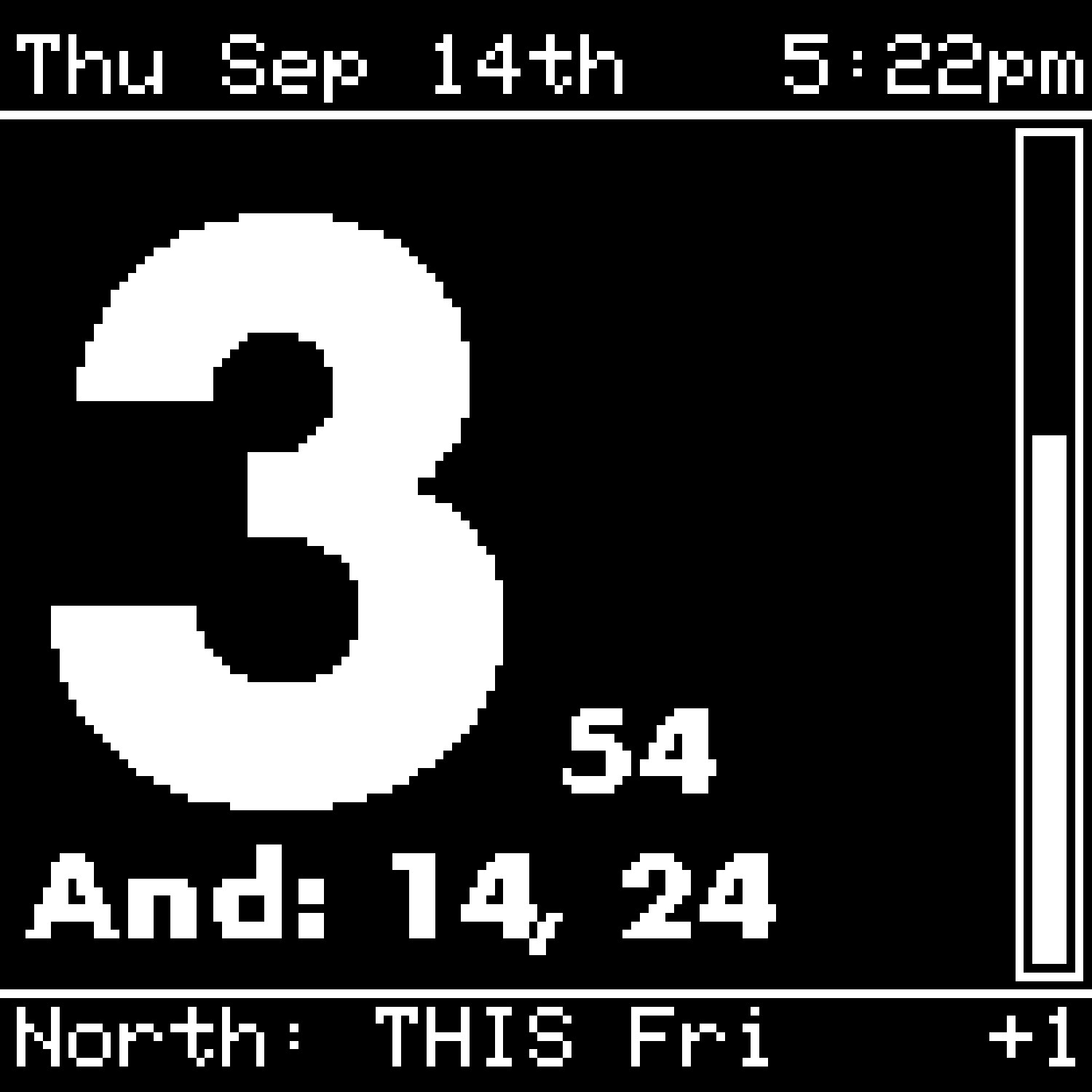

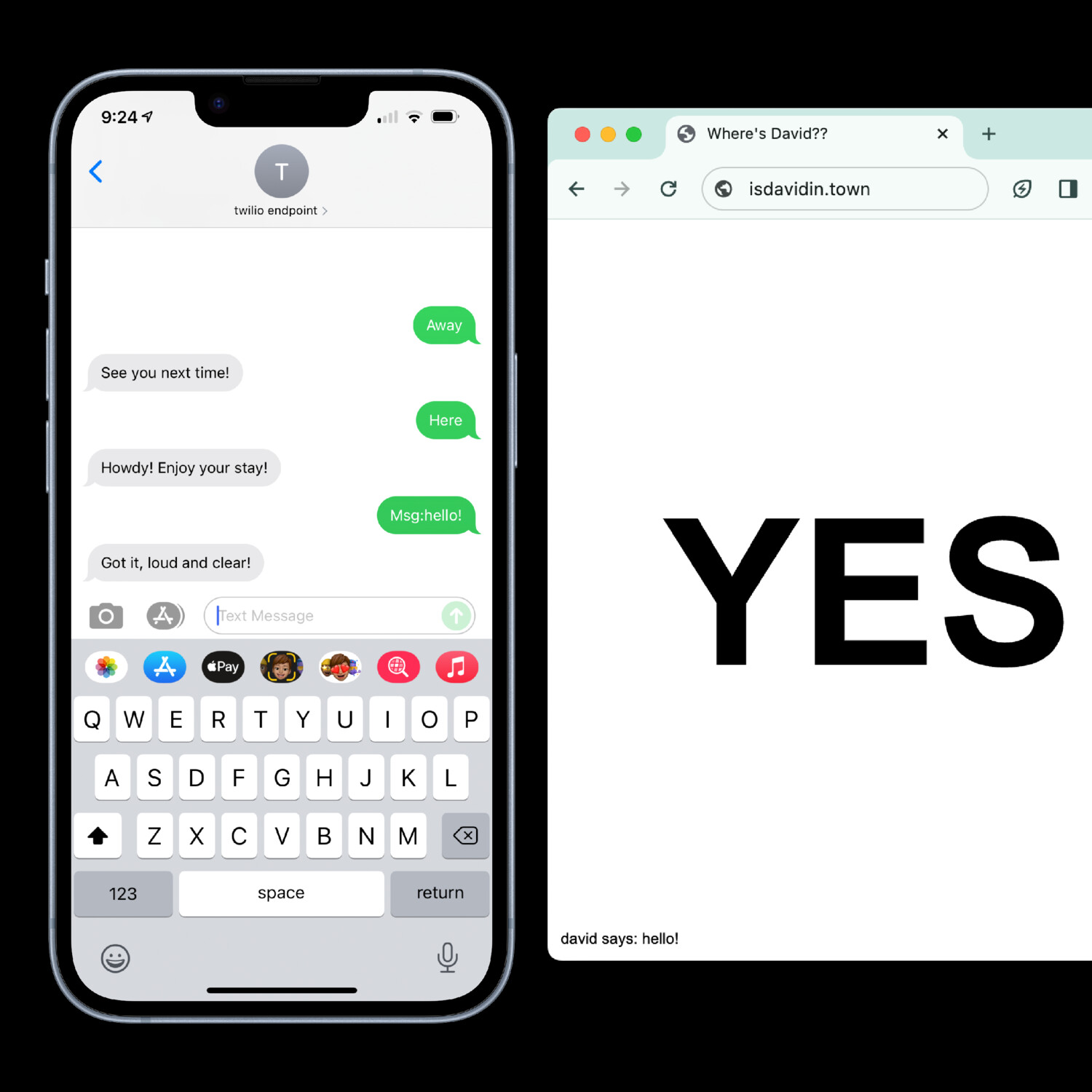

In 2021, I started riding the Muni N-Judah downtown almost every day. I found myself checking my phone each morning while getting ready to see the departure times, and wanted something more accessible. I threw together this little "screen in a box" with an ESP32 I had laying around and have been using it ever since. It even alerts me when street cleaning is imminent!

Project Included

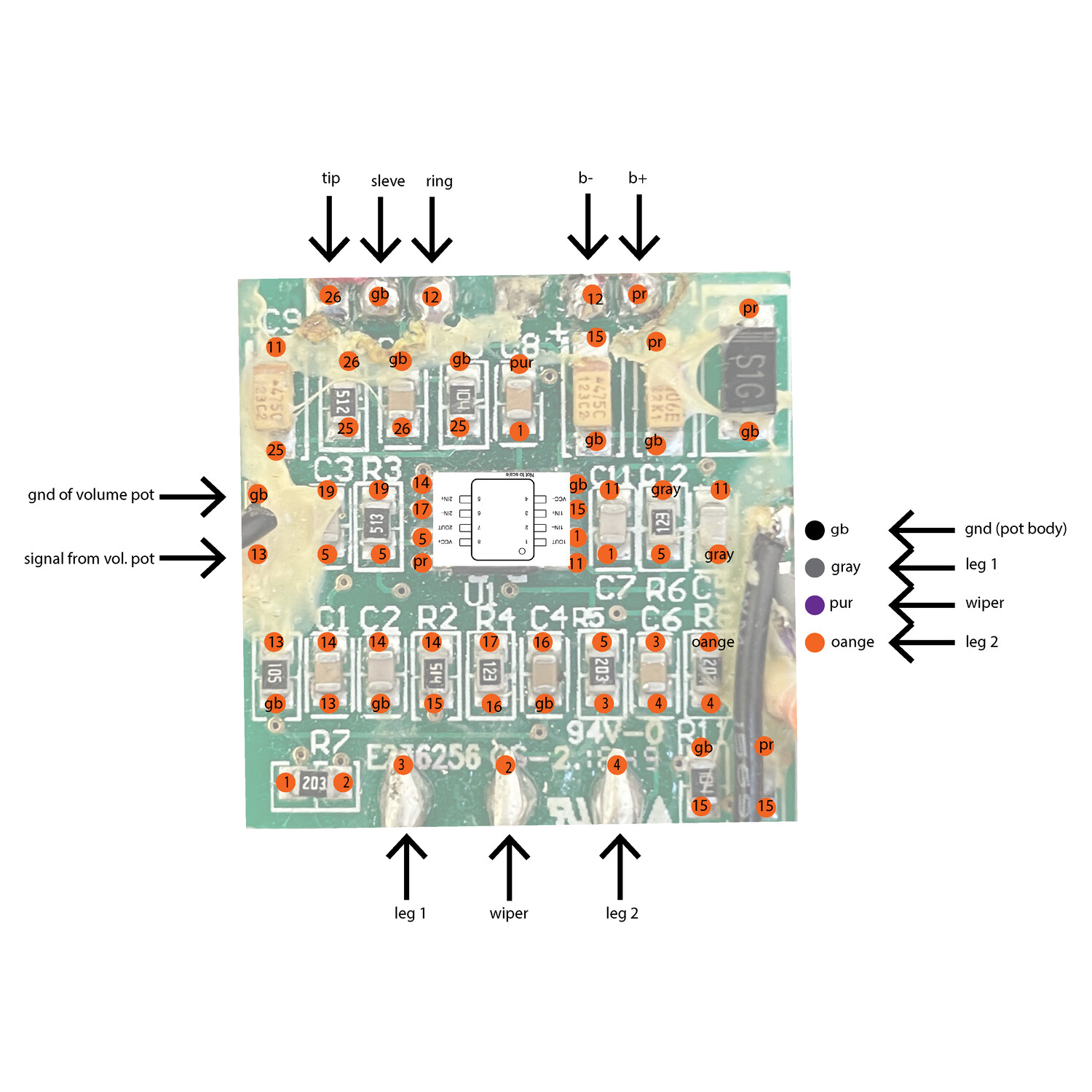

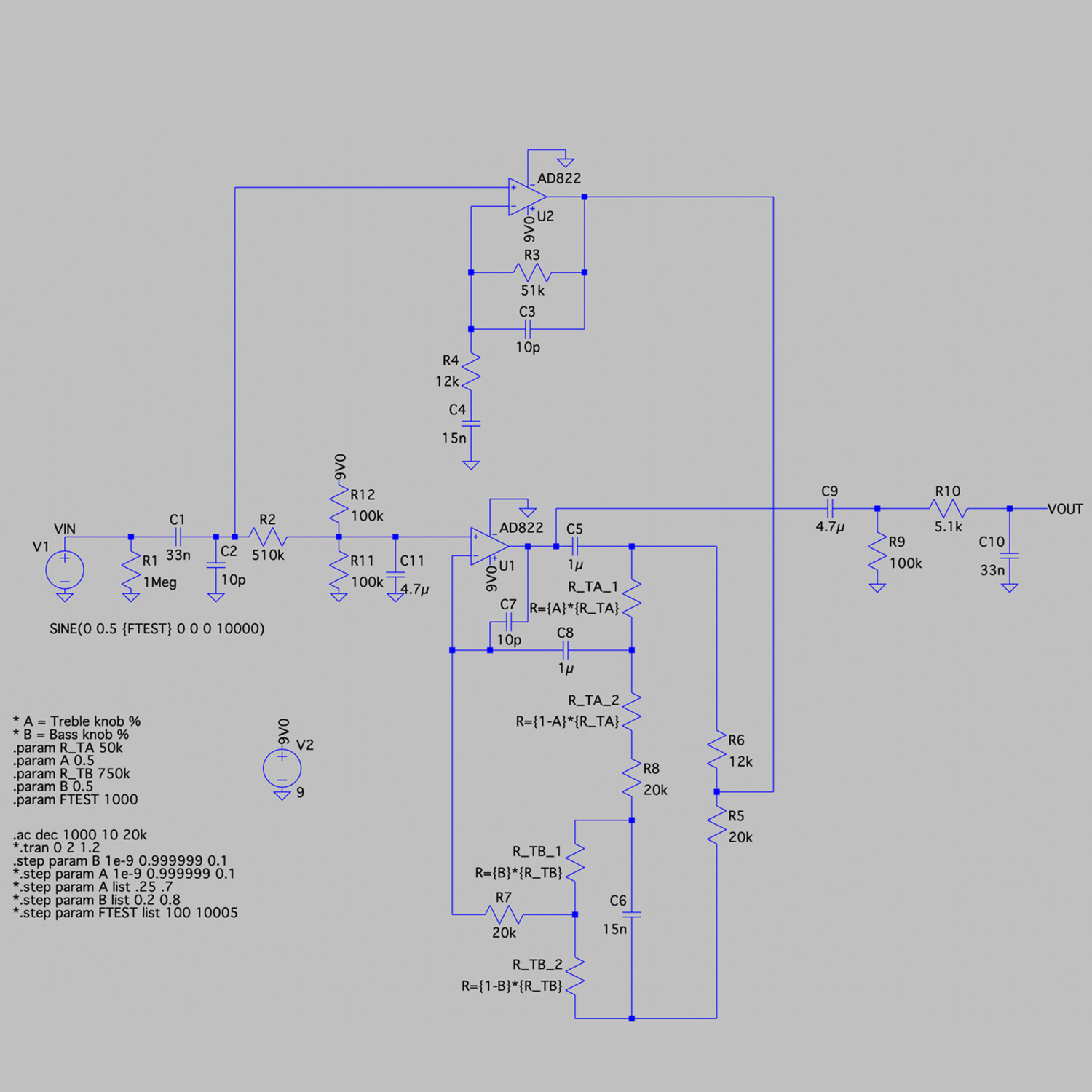

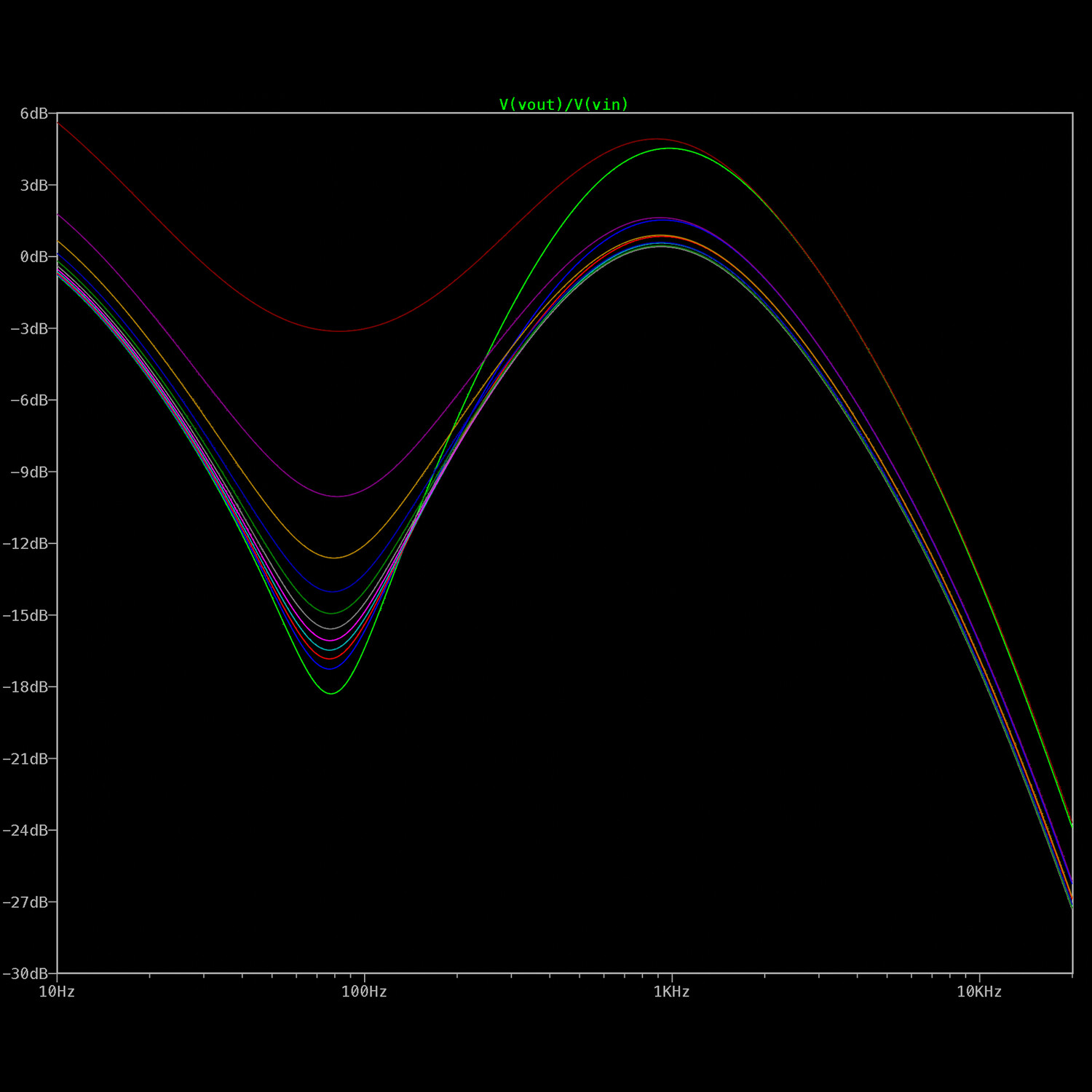

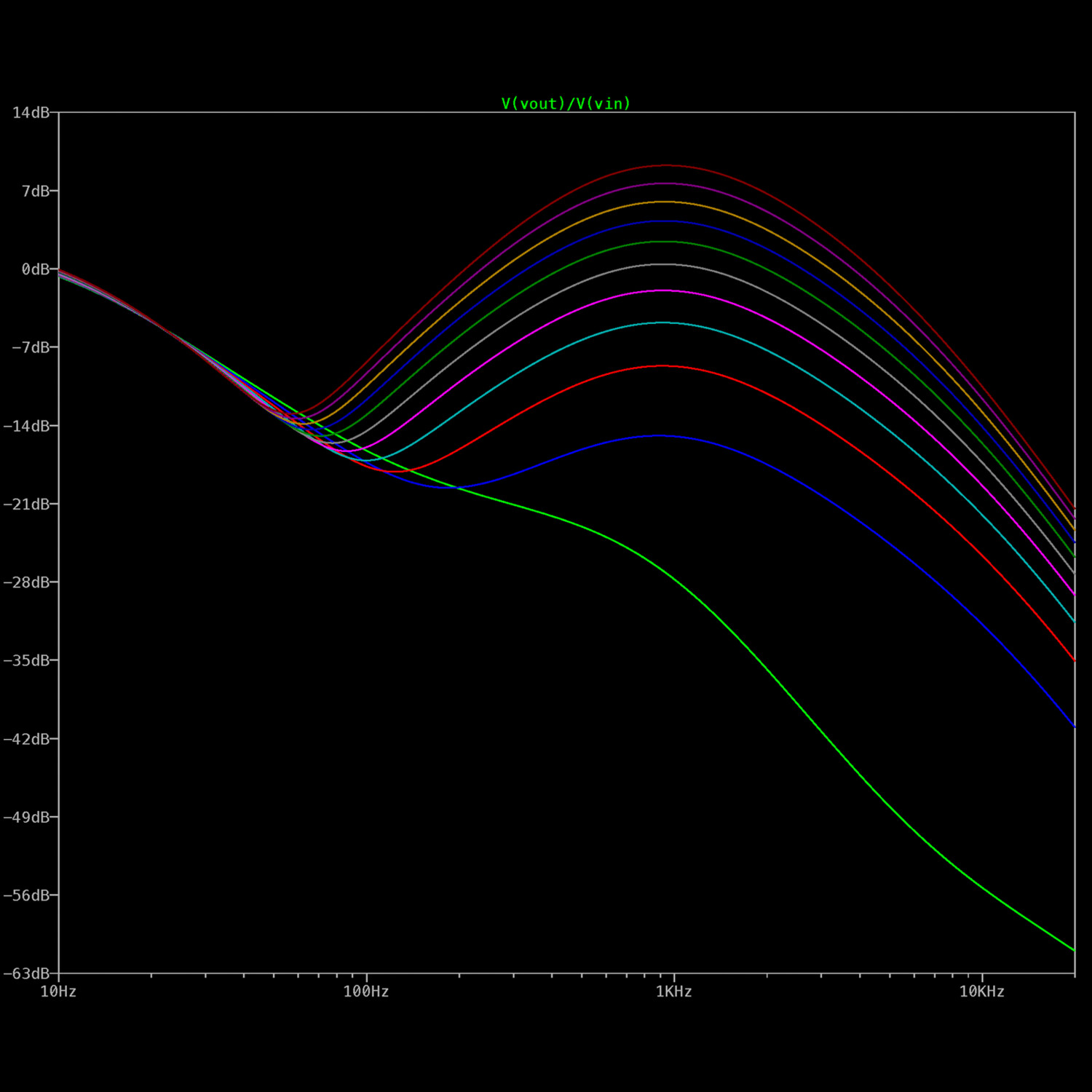

My bass guitar had been starting to get flaky. When a new battery and new 1/4" jack didn’t solve the problem, I took the opportunity to dig a little deeper into the circuits inside the bass.

Project Included

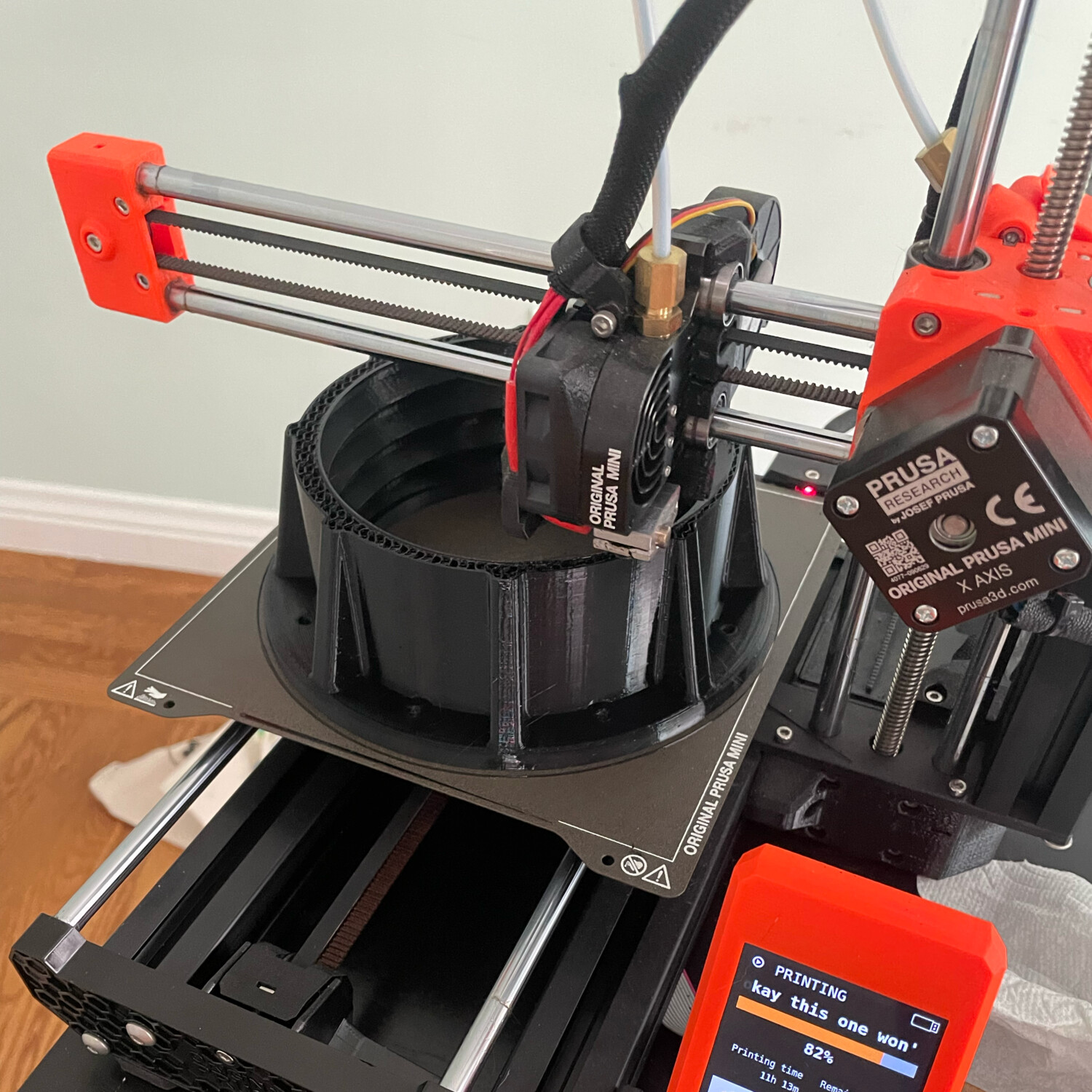

Swamp coolers are a simple way to make cold air in dry environments - at Burning Man, the Playa Labs “figjam” swamp cooler might be the canonical swamp cooler due to its simple design, so I built one, making some key improvements along the way.

Project Included

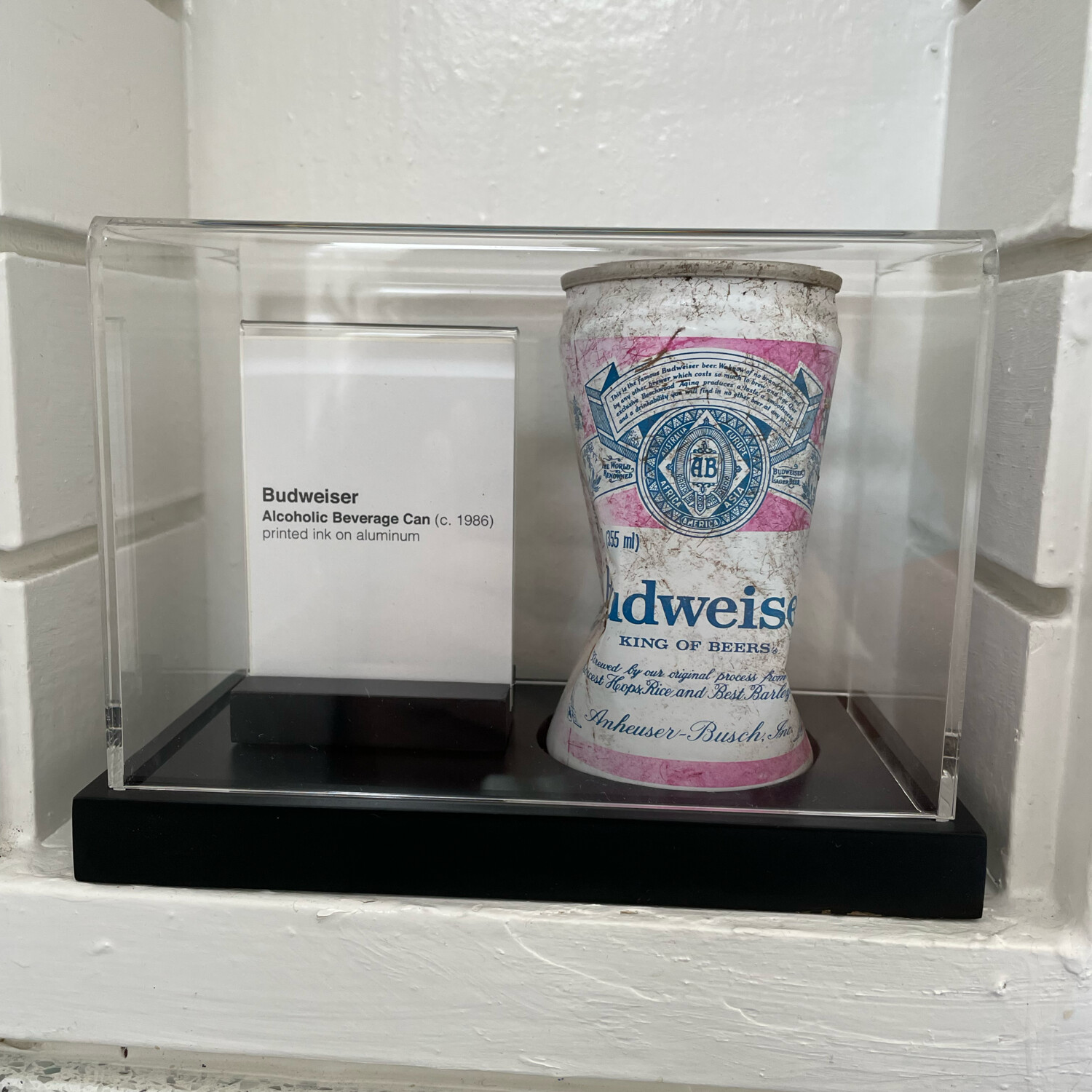

I love making things with my hands and having a good time. To those extents, enjoy this smorgasbord of random small projects I’ve done in the last few years!

Projects Include

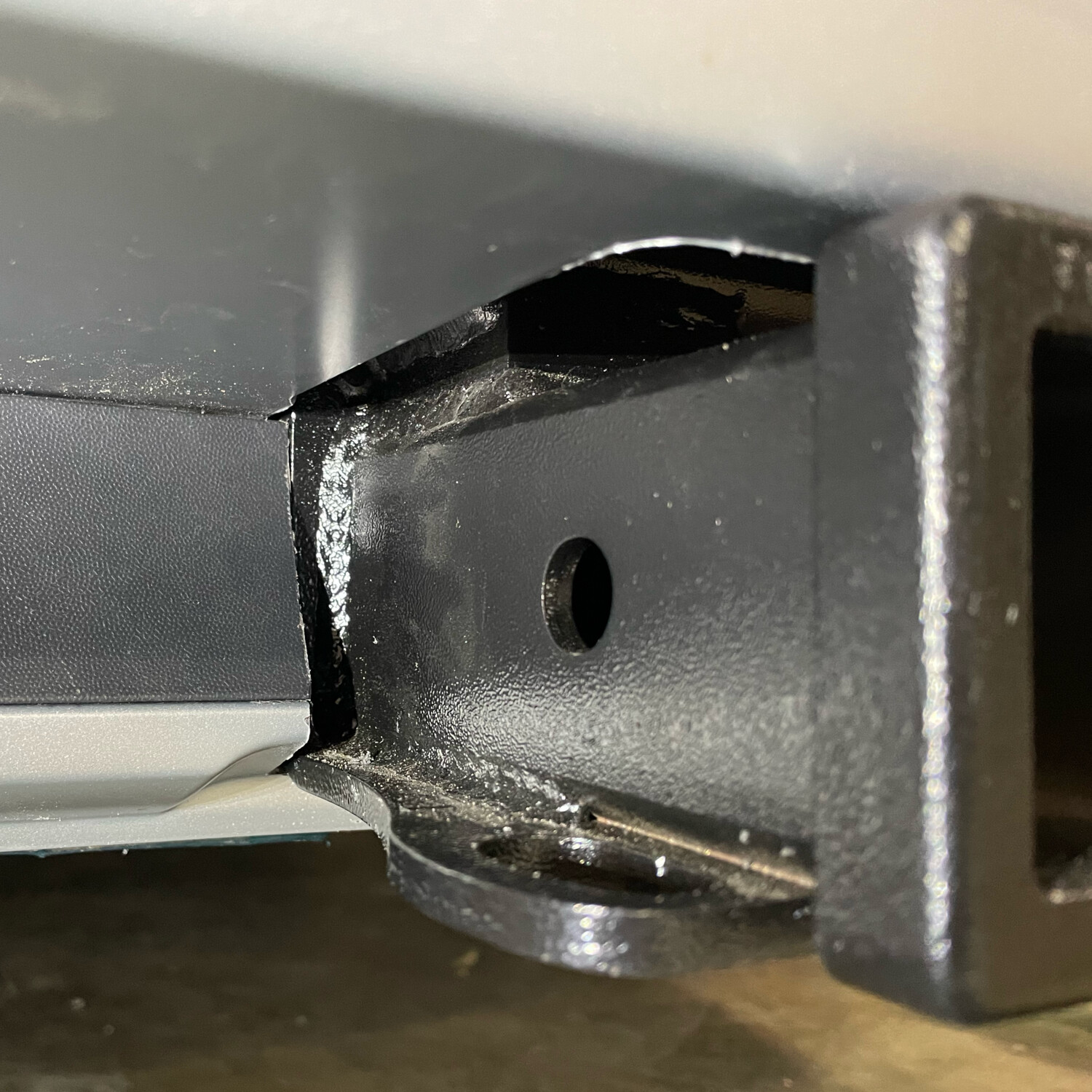

In college I drove a 1973 VW Super Beetle around Atlanta (somewhat masochistically, I might add, given the lack of A/C in the Georgia heat). For better or worse, it gave me the car-work itch. In college, amongst all of the normal maintenance items like adjusting the valve lash and setting the timing, I rebuilt the engine from scratch, restored the suspension, and upgraded the brakes. Since then, I haven’t been able to escape the occasional car project. Here’s a sampling of car stuff I’ve been up to lately.

Projects Include

click to close